As a crucial element of manufacturing production lines from food to pharmaceuticals, textiles to timber, metal detectors help protect processing machinery from damage while safeguarding consumers from hazardous physical contaminants.

In this article, we’ll explore how industrial metal detectors work to ensure quality, safety, and continuity of production.

What is Metal Detection?

Metal detection is the process of using electronic systems to sense the presence of physical metal contaminants and remove contaminated materials or products. Metal detectors “see” magnetic and/or conductive physical contaminants as something that disrupts a controlled magnetic field.

- Ferrous metals contain iron and exhibit magnetic and conductive properties, making them easy to detect.

- Non-ferrous metals (e.g. aluminum, copper, tin, brass) are conductive but non-magnetic, making them more difficult to detect.

- Stainless steel has low conductivity and very low magnetism; it is the most difficult to detect.

The key to a successful metal detection system is optimizing system fields and frequencies to allow the detector to accurately sense metal contaminants while ignoring product effect—the magnetic or conductive effects of a product’s configuration, ingredients, moisture, or packaging.

What is a Transmitter Field?

Metal detectors have two primary elements for sensing metal: transmitter and receiver coils.

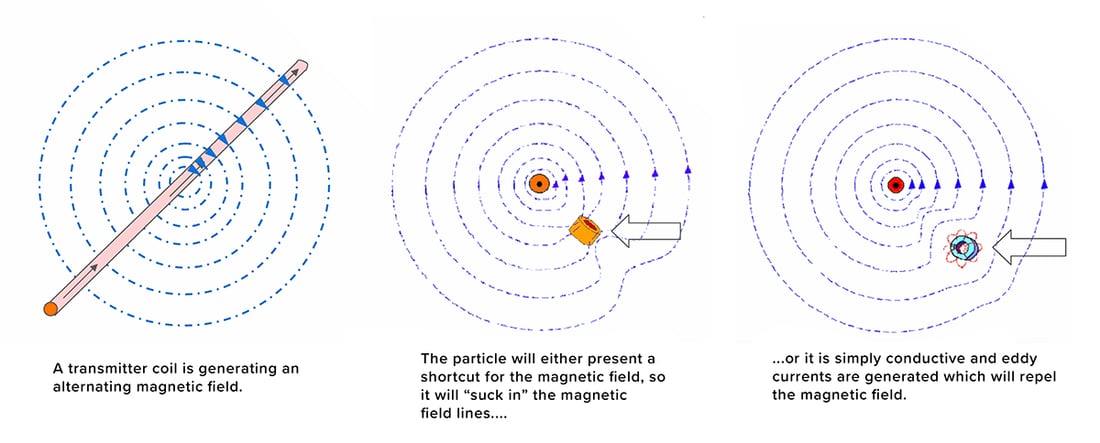

- The transmitter coil generates an alternating magnetic field, also referred to as the transmitter field.

- The receiver coil senses and reacts to local changes in the transmitter field.

Imagine the transmitter field as a patterned group of lines. When a metal contaminant passes through the field, it disrupts the pattern. A magnetic contaminant will create a new path for the field to follow and change the direction of the field lines. A conductive contaminant will create eddy currents that repel the magnetic field lines. In either case, the receiver coil detects the geometric distortion of the transmitter field, and triggers an alarm, allowing the metal detection system to reject the contaminated product from the process flow.

As mentioned in the previous section, one key piece to a successful metal detection system is optimizing system fields while ignoring product effect. Your product’s contents, packaging, or orientation can affect the transmitter field similarly to a physical contaminant. Moisture, salt, and metalized packaging can cause field distortion as they are all mildly conductive, Iron-rich foods like fortified cereals can mimic the field distortion of a contaminant as well. These influences are referred to as “product effects,” and they represent the primary challenge to ensuring consistent and accurate metal detection.

What are Metal Detection Frequencies?

Frequency is an indication of how often a radio wave oscillates in one second expressed in hertz, Hz. If a given wave repeats itself 12 times per second, its frequency is 12 Hz. A wave that repeats itself 15,000 times per second has a frequency of 15 kHz (kilohertz).

How do Frequencies Act Like a Tuning Fork?

Traditional metal detectors are optimized to give the best detection using a single-tone frequency signal for the transmitter field. They discriminate product from metal by looking at the amplitude of the receiver signal and a small shift of the receiver signal relative to the transmitter field. This shift is called phase angle and is measured in degrees.

Traditional metal detectors are optimized to give the best detection using a single-tone frequency signal for the transmitter field. They discriminate product from metal by looking at the amplitude of the receiver signal and a small shift of the receiver signal relative to the transmitter field. This shift is called phase angle and is measured in degrees.

The operation frequency of these single-frequency metal detectors is defined prior to fabrication of the sensor head and cannot be altered during operation. This is similar to a tuning fork, which is also manufactured to a single specific frequency. The fixed frequency is chosen based on the properties of the product to be inspected. It may also depend on the variety of metal grades expected to occur.

CASSEL Inspection’s approach to metal detection uses a doubly resonant “tuning fork” design, which combined brings the benefit of using multiple frequencies simultaneously.

Processors running different types of products or encountering varying metal grades can utilize a metal detector with multiple “tuning forks”—several fixed frequencies set during the detector’s fabrication. A four-frequency system could run a low frequency range like 35, 75, 150, and 300 kHz, or a higher range such as 75, 150, 300, and 600 kHz based on requirements for detecting ferrous or non-ferrous metals.

How are Metal Detection Frequencies Managed?

Detection frequencies are chosen either manually or automatically when a product is run for the first time. This process is called “Product Teach.” Optimal detection parameters for the product are stored in the metal detector’s product memory and automatically recalled when the product is run again.

Ferrous vs Stainless Steel

Ferrous material is best detected at lower frequencies. This is because product signals are smaller at low frequencies. Stainless steel is more easily detected at high frequencies, although product signals are also larger at higher frequencies. Thus, operation at a single frequency will always require balancing the detection target and product effect.

At CASSEL Inspection we offer a range of MultiSense metal detectors. Two frequencies are chosen at the time of manufacture and the metal detector operates on both tuned frequencies at the same time, offering better discrimination compared to single frequency detection, while maintaining most of the signal quality of a tuned single-frequency system. Essentially this means two different “tuning forks” are operating at the same time.

Why Not Use 100 Metal Detection Frequencies?

For technical reasons, the simultaneous operation of tuned frequencies is limited to very few frequencies. Other technical approaches to multi-frequency, multi-spectrum detection are either rapidly switching between several different frequencies or simultaneously operating on many frequencies. In theory, these approaches give processors the choice of many frequencies, giving even more information to discriminate the product from metal as compared to single-frequency detection. However, in practice, utilizing multiple detection frequencies sacrifices the very high signal quality available from a properly tuned and optimized single-frequency sensor. Therefore, the advantage over optimal single-frequency detection is only moderate because the benefit of a single continuously operated tuning fork generating a very clean primary signal is lost.

The balance between single- and multi-frequency detection is critical and finding the right metal detector for your unique application can help improve many aspects of product line optimization and quality.

CASSEL SHARKⓇ metal detectors offer the option of single-frequency, fixed-frequency, and multi-frequency metal detection solutions that can be customized to meet specific product and process needs. Learn more about how metal detection protects your systems, your products, and your customers.