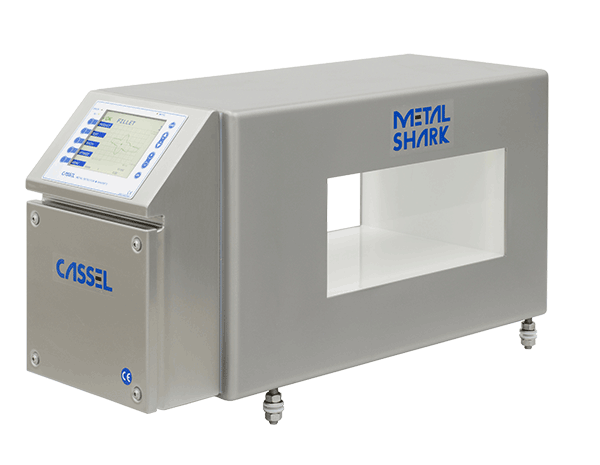

METAL SHARK® BD

- Reliably detects metals in packaged and upackaged products on conveyor belts

- High sensitivity in dry, moist, salty or frozen goods with 3D detection

- Easy setup and intuitive operation due to auto-calibration and TeachAssistant

- Maintenance-free design with automatic and continuous calibration of detector coils

- BRC-Kit option: Conformity with the Global Standard of the British Retail Consortium (BRC) for food safety

- Special models: UltraSens for even better sensitivity or Twinhead model to overcome orientation effects

Features

- Maximum detection performance with high accuracy in the detection area due to 4-quadrant technology

- Stable against temperature or product changes through 3D detection

- Storage spaces for up to 250 products

- Easy to use with intuitive and multilingual menus

- Documentation of all events and metal messages

- Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

- Cyclical function monitoring with Performance Validation System (PVS)

- Available as a system solution with additional devices

Function

The METAL SHARK® BD is used free-standing or combined with conveyor belts or chutes. Using 3D detection technology, it detects the smallest magnetic and non-magnetic metal contaminants (iron, stainless steel, aluminum etc.) precisely and reliably even under difficult conditions.

The robust, closed stainless steel housing is easy to clean and therefore ideally suited to the food industry.

Image Gallery

Delivery Scope

- Sensorhead BD

- Controller METAL SHARK®

- Optional: system solutions with standardized or individual conveyor belt

- Optional: individual rejection solutions possible

Application

- monitoring of packed or loose goods free or on conveyor belts or chutes

- quality assurance for incoming goods, outgoing goods or during running production

Specifications

| Model Name/ID | METAL SHARK® BD |

| Electronics | digital signal processor, noise filter, digital balance control, digital frequency control, PowerDrive circuit |

| Input | 8 freely configurable 24 V DC signals, e.g. for reject confirmation or conveyor belt control |

| Output | 2 potential-free: "Error" and "Metal" 8 freely configurable 24 V DC signals, e.g. for optic/acoustic alarm or start conveyor belt |

| Inspection Method | Inductive, multi channel operation, balanced receiver coils |

| Metal Detection | Ferrous, non-ferrous (e.g. aluminium or copper) und stainless steel |

| Product Compensation | 250 storage spaces, compensation performed automatically, with Teach-Assistant |

| Protection Type | IP65, optional IP66 or IP67 |

| Ambience | Standard: -10°C to +40°C, rel. humidity 30% up to 80% (non condensing) Optional: -40°C or +55°C |

| Product Temperature | Standard: -30°C to +40°C Optional: -40°C to +60°C |

| Power Supply | One phase 110-240 VAC, 50/60 Hz, typ. consumption 20 W (max. 60 W) |

| Interface | RS232, LAN (optional, for SHARKNET®), USB (optional) |

| Maintenance | Maintenance-free, self calibrating sensors |

| Diagnostics | Integrated diagnostic software, automatic self-test |

| Conformity | CE |

Accessories & Extras

The METAL SHARK® BD can be perfectly adapted to your production by various special designs and accessories. Different temperature or hygiene requirements are taken into account as well as complicated product requirements for metal detection. For your audit reliability, a Performance Verification Certificate can be issued by CASSEL service technicians during commissioning or maintenance.| 3D-detection | Additional photocells and upgraded control software (BOOST FACTOR) enable accurate evaluation during the detection period of each item inspected (MultiPhase). |

| Multi-frequency | Provides selection of four different frequencies, resulting in significantly increased performance in situations where product variations occur (density, location/position, temperature, etc.). |

| Temperature extension cold | Temperature range extended to -40°C (-40° F), resin seals remain elastic at low temperatures. Special insulation, heated enclosure and other features. |

| Temperature extension hot | Temperature range extended to +55° C, (+131° F), adapted enclosure, additional thermal insulation, replaceable filter fan, heat exchanger and/or active cooling units. |

| High temperature extension for goods inspected | Goods temperature up to +120°C (248° F) max. This option provides IP54 grade enclosure for the sensor. |

| LPW/HPW | IP enclosure upgrade through adapted sensor seal, installation of additional seals and dual housing for the controller electronics. |

| Signaling devices (optical/acoustic) | Stacking lights and signal horns/sirens available in different versions and IP protection classes. |

| Control unit | The control unit is mounted on the sensor as standard, wall mounting is also possible. |

| Twinhead version | To overcome the orientation effect, whereby conductive or magnetic contaminants run parallel to their respective fields, a special twinhead version is available. Two metal detectors at a 90° angle to one-another offset to ensure metal detection even in such cases. |

| UltraSens model | Fast Power Drive (FPD) significantly enhances metal detection and reliability in industrial environments that fail to comply with pertinent electromagnetic compatibility standards. Available with a range of enclosure grades. |

| Ferrous in Foil model | Special version for detecting magnetic metals packaged in aluminum-coated foils or aluminum trays. |

| SHARKNET® | The SHARKNET® software connects METAL SHARK® metal detectors with a central computer, providing centralized storage of all operating data plus batch and alarm documentation for HACCP and IFS compliance. |

| Performance Verification Certification | Issue of a Performance Verification Certificate (proof of functionality for audits) by CASSEL service technicians, e.g. during commissioning or maintenance possible. |

| BRC-Kit | With the optional BRC kit, the device meets the requirements of the Global Standard of the British Retail Consortium (BRC) for food safety and thus also the established and generally recognized standards for HACCP and IFS. |