METAL SHARK BD-E2 MEAT

- Reliably detects metals in raw or frozen meat in standardized E2 boxes

- Especially high sensitivity with moist or frozen products with 3D detection

- Easy setup and intuitive operation with Autocalibration and TeachAssistant

- Maintenance-free design with automatic and continuous calibration of detector coils

- BRC-Kit option: Conformity with the Global Standard of the British Retail Consortium (BRC) for food safety

Features

- Maximum detection performance with highest reliability in the entire detection area due to 4-quadrant technology

- Stable against temperature or product changes with 3D detection

- Simple setup with TeachAssistant

- Memory for up to 250 products

- Easy to use with intuitive and multilingual menus

- 4-level password system, automatic log out after time lapse

- Documentation of all events and metal messages

- IFS and HACCP reports (metal alarm, batch, product, technical status of detector and all changes) available on the display at the touch of a button

- Optional: Data transfer to USB interface or connection to the company network via SHARKNET software

- Performance Validation System (PVS) regularly reminds you of necessary performance validation with different metals and sphere sizes

- Available as a system solution with additional devices like railings, lights, different kinds of rejects etc.

Function

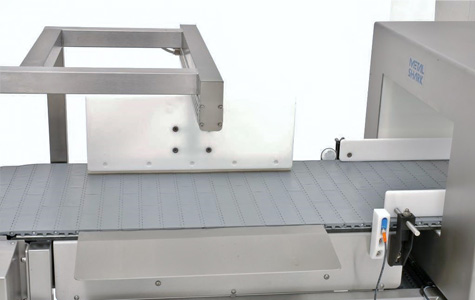

The METAL SHARK BD-E2 MEAT is used free-standing or combined with conveyor belts. Using 3D detection technology, it detects the smallest magnetic and non-magnetic metal contaminants (iron, stainless steel, aluminum etc.) precisely and reliably even under difficult conditions.

The robust, closed stainless steel housing is stable and easy to clean – ideally suited to the meat industry.

Image Gallery

Delivery Scope

- Detection unit (sensor) BD

- Controller METAL SHARK

- Conveyor HQ

Application

- Monitoring of packaged and unpackaged goods on conveyor belts

- Quality assurance for incoming goods, outgoing goods or during running production

- Machine protection, e.g. in meat processing

Specifications

| Model Name/ID | METAL SHARK BD-E2 MEAT |

| Electronics | Digital signal processor, noise filter, digital balance control, digital frequency control, PowerDrive circuit |

| Input | 8 freely configurable 24 V DC signals, e.g. for reject confirmation or convyeor belt control |

| Output | 2 potential-free: "Error" and "Metal 8 freely configurable 24 V DC signals, e.g. for optic/acoustic alarm or start conveyor belt |

| Inspection Method | Inductive, multi channel operation, balanced receiver coils |

| Metal Detection | Ferrous, non-ferrous (e.g. aluminium or copper) und stainless steel |

| Product Compensation | 250 storage spaces, compensation performed automatically, with Teach Assist |

| Protection Type | IP65 (IEC 60529) IP66 possible with surcharge LPW-/HPW |

| Ambience | Standard: -20°C to +40° C, rel. humidity 30% up to 80% (non condensing) |

| Product Temperature | Standard: -30°C to +40°C Optional: -40°C to +60°C |

| Power Supply | 220-240 VAC, 1ph, 50-60 Hz |

| Interface | RS232, LAN (optional, for SHARKNET), USB (optional) |

| Maintenance | Maintenace-free, self calibrating sensors |

| Diagnostics | Integrated diagnostic software, automatic self-test |

| Conformity | CE |

Accessories & Extras

The METAL SHARK BD can be adapted to your production process. Different temperature or hygiene requirements are taken into account as well as complicated product requirements for metal detection.

For your audit reliability, a Performance Verification Certificate can be issued by CASSEL service technicians during commissioning or maintenance.

| 3D Detection | Additional light barriers and update of the control software (BOOST factor) enable an exact signal evaluation over the detection period of each individual product (MultiPhase). |

| Multifrequency | Use of 4 different frequencies significantly increases the stability against product variations (density, position, temperature, etc.) |

| Temperature extension cold | Temperature range extended to -40°C, cold-elastic grouting material, insulation, switch cabinet heating and other measures |

| Temperature extension hot | Temperature range extended to +55° C, Adaptation of control cabinet, additional thermal insulation, replacement of filter fan, heat exchanger and/or active cooling units |

| High temperature extension for product | Product temperature up to max. +120°C, with this option, the sensor has protection class IP54 |

| LPW/HPW | Increase of the IP protection class by adapting the sensor seal, installing additional seals and a double housing for the control electronics |

| SHARKNET® | The SHARKNET® software connects METAL SHARK® metal detectors to a central computer and offers central storage of all operating data as well as batch and alarm documentation for HACCP and IFS conformity. |

| Twinhead design | Special version for the detection of difficult contaminants: Magnetic chips can, for example, align themselves on the conveyor belt so that they run perfectly parallel to the magnetic field and thus remain undetected. Two magnetic fields offset against each other ensure metal detection even in such cases. |