Five Factors to Check Before You Buy a New Metal Detector

Metal detectors are engineered to identify the presence of iron, non-ferrous metal, or stainless steel within a product stream, and once detected, reject the contaminated product. Unfortunately, it can happen that detectors erroneously identify metal where there is none, leading to the destruction of good products. The metal detector is not always the source of error, some problems can be easily and inexpensively remedied.

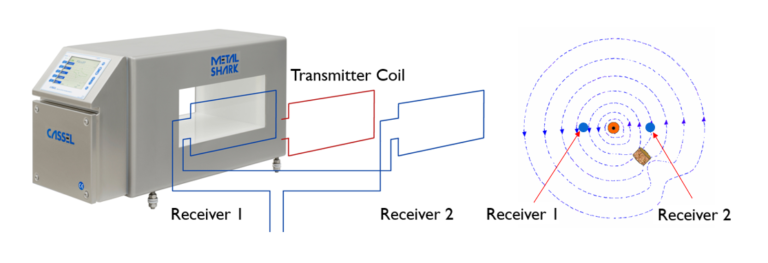

How a Metal Detector Works

Most industrial metal detectors operate on a simple transmitter-receiver principle with so-called “balanced coils”. The device is equipped with a total of three coils. The transmitter coil builds up an electromagnetic alternating field similar to a radio transmitter. The other two coils receive the signals of this magnetic field.

In an undisturbed situation, this field “looks” the same for both receivers – it is “balanced“. As soon as a metal part passes the detector, a disturbance of the magnetic field occurs, which is detected by the receiver coils, they register an imbalance. This disturbance depends on the conductivity and magnetic properties of a material:

- Ferrous metals are magnetic and conductive, generating a strong interference signal.

- Non-ferrous metals such as aluminum or brass are good conductors, though they are not magnetic. They also generate a strong interference signal.

- Stainless steel is usually non-magnetic and does not conduct electricity very well. Its interference signal is therefore significantly weaker than that of iron or non-ferrous metals.

But not only metals are “seen” by a metal detector. Other substances, such as salt or even water, are conductive and influence the magnetic field. The software of a good metal detector must therefore evaluate the different interferences of the magnetic field and distinguish the specific interference signal of a metal particle from other influences. To do this, every manufacturing detector “learns” the specific signals of the products will have to examine later. If, during the production process, the signal of a product deviates from the previously “learned” structure, the detector recognizes this as metallic contamination.

The smooth operation of a metal detector can be compromised by various influences, which lead to false rejections. However, some of these can be easily identified and quickly eliminated.

Five Factors to Check

If you believe your detector conspicuously and often erroneously identifies metal contamination, then you should check the following points.

1. Interference From Other Machines

A frequent but very easily corrected error is interference from other machines or metal parts in the vicinity of the detector. Metal detectors work with electromagnetic signals that radiate in waves around it. The field generated by this can easily extend beyond the detector into the environment. Accordingly, the receiver coils detect metal or other devices in their environment that work with similar signals.

A frequent but very easily corrected error is interference from other machines or metal parts in the vicinity of the detector. Metal detectors work with electromagnetic signals that radiate in waves around it. The field generated by this can easily extend beyond the detector into the environment. Accordingly, the receiver coils detect metal or other devices in their environment that work with similar signals.

If false rejects occur “all of a sudden” check for:

- Frequency converters, cables or drives that were not there before in the vicinity of the detector

- Metallic parts like railings or conveyors that protrude into the “metal-free zone” around your detector

- Metallic equipment like pallet trucks stationed too close to the metal detector

Lift trucks are valuable helpers, but should not be used or parked directly next to detectors.

2. The Packaging: Metallized Foil

You changed the packaging of your products to metallized foil? Good decision for storing and presenting products, but products that are packaged in metallized films are difficult to test for metallic contamination.

Searching for impurities with a metal detector in such products bears a high risk of flawed inspection results. So an X-ray scanner is the better option for reliably checking your products for foreign objects.

3. The Environment: Temperature and Humidity

Metal detectors are quite stable against temperature or humidity when correctly adjusted. Nevertheless, these factors can play a role if they fluctuate strongly or change significantly after the installation and setup of the detector.

So, if suddenly increased false rejections occur, it may be useful to check the following:

- Does the ambient temperature fluctuate strongly during the day since the metal detector was installed?

- Is it generally significantly higher or significantly lower than when the device was installed?

- Has the air humidity increased noticeably, e.g. due to cleaning cycles?

If so, it may be useful to “relearn” the tested products again under the new ambient conditions.

4. The Product

Frozen fish can be difficult to inspect, especially if it is salted or starts melting.

Frozen fish can be difficult to inspect, especially if it is salted or starts melting.

Products usually have their own conductivity, albeit very low. Different ingredients influence this conductivity. If this influence is too strong, it can lead to disturbances of the detector sensitivity.

- Moisture: Animal products such as fish, meat or cheese have a high water content. This can vary over the course of a day which also changes the strength and conductivity of the products. This can influence the “speed” at which the magnetic waves can penetrate the product sufficiently to create defects. Good detector software compensates for such effects. Nevertheless, it is worthwhile to control factors such as temperature and humidity.

- Salt: Salt is more conductive than many other substances that are usually found in food and can influence a magnetic field accordingly. If you are testing salty products such as chips, nuts or almonds for metallic impurities, the detector should be specially adjusted for this type of product. If false rejections occur more frequently than before, check the settings of your detector for salty products.

- Temperature: When warm products cool down along the production line or frozen products thaw, they also change their conductivity. This can go so far that these changes affect the product signal. Check whether significant temperature changes could be caused by longer transport distances or fluctuations in ambient temperature.

5. The Detector Itself

Advanced metal detection devices are designed to provide maximum sensitivity to contaminants while maintaining high immunity to interference. They can also be trained for specific products, so that later product changes can be carried out quickly and easily – with settings perfectly adapted to each product.

All METAL SHARK models have a product memory for up to 250 products. In most cases with suddenly increased false rejects it is sufficient to “train” the detector again for the specific product and to store the settings for the future.

Reduce false rejects and detect up to 50% smaller metal fragments with Shark® MultiSense™. See how our new technology can help you.