Baked Goods Reliable inspection to ensure product quality and safety.

Bakery Product Inspection: Ensuring Safety and Quality in Baked Goods

Whether it’s hamburger buns, cupcakes, or cookies, ensuring that bakery products remain free from physical contaminants throughout production is a critical priority.

From raw ingredients to packaged bakery goods, physical contaminant inspection plays a significant role in protecting consumers, preserving brand reputation, and maintaining regulatory compliance. CASSEL Inspection offers a range of inspection systems designed for seamless incorporation into any bakery production facility.

Physical Contaminant Inspection: Why Do Bakery Brands and Facilities Need It?

Physical contaminant inspection systems support facility-wide quality and safety programs, mitigating product recalls and the associated logistical, financial, and reputational effects.

CASSEL Inspection provides advanced metal detection, X-ray inspection, and checkweighing solutions designed to meet the unique challenges of bakery production.

These inspection systems seamlessly integrate into any stage of the baking process, including:

- Raw ingredient intake: Ensuring bulk ingredients such as flour, sugar, and chocolate are free from contaminants.

- Processing: Detecting foreign materials introduced during mixing, baking, and handling.

- Packaging: Verifying the safety and consistency of finished, wrapped, or boxed products.

With consumer safety at stake and increasing regulatory oversight, bakery facilities need reliable inspection solutions to protect their products and their reputation.

How is Metal Detection Used in the Bakery Industry?

Metal contamination in baked goods production can originate from multiple sources, including raw ingredients, processing equipment, and packaging. CASSEL Inspection’s metal detection systems help manufacturing facilities in the bakery industry maintain the highest quality standards by identifying and removing metal contaminants at key production points.

Metal detectors are ideal additions to all critical control points (CCPs) because they are tailored to meet processing needs and adapt easily to any stage of production.

Bulk Ingredient Inspection

Custom metal detection systems allow for efficient and effective inspection of high-volume bulk flow materials such as flour, sugar, and other baked product ingredients.

- Gravity-feed metal detectors screen bulk flour, sugar, and other ingredients before they enter the mixing stage.

Learn more about how gravity-feed metal detectors identify physical contaminants in bulk ingredients.

In-Process Inspection

During the processing stages of bakery item production, foreign materials can be introduced accidentally by mixers, choppers, cutters or any metal items upstream in the process. Common metal contaminants include screws, nails, metal shavings, and chips from spatulas or aluminum baking trays.

- Conveyor-style metal detectors can inspect baked goods during the production phase or before or after packaging.

- Conveyor-style metal detectors can inspect bulk-flowing materials in widely varying volumes.

See how conveyor belt metal detectors identify physical contaminants during the processes phase of bakery product manufacturing.

Final Package Inspection

Some bakeries prefer to inspect products once they are boxed, adding another layer of safety to the process. Post-packaging physical contaminant inspection is ideal for removing any process-related foreign material contamination and eliminating the risk of contaminated products leaving your facility.

If you are looking for physical contaminants in your finished products, a conveyor belt inspection system can help! CASSEL Inspection’s METAL SHARK® metal detectors provide highly sensitive and customizable detection for a variety of bakery goods, ensuring product integrity at every stage.

Baked Product X-Ray Inspection

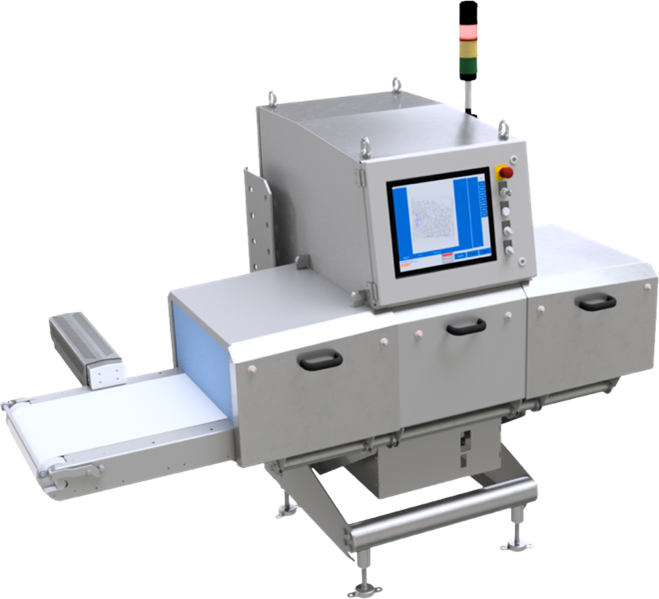

Once baked goods leave the oven, ensuring they are free from contaminants is critical before packaging and distribution. X-ray inspection provides a highly effective solution for detecting foreign materials, but products must be inspected without compromising their texture or quality.

For products like cookies, pastries, and breads that move along a conveyor belt, CASSEL’s curtainless X-ray inspection systems offer an ideal solution. Traditional X-ray systems use heavy shielding curtains that can drag across delicate baked goods, potentially causing damage or contamination. Curtainless X-ray technology eliminates this concern, providing uninterrupted inspection without direct contact with the product.

Key benefits of curtainless X-ray inspection for baked goods include:

- Gentle product handling: No risk of damaging soft, crumbly, or fragile items.

- Superior contaminant detection: Identifies foreign materials, even in complex, multi-layered products.

- Continuous inline inspection: Seamlessly integrates with conveyor systems for high-speed production lines.

- Hygienic design: Reduces the risk of cross-contamination and ensures compliance with food safety standards.

By incorporating advanced X-ray inspection into your baked goods production line, you can maintain quality, protect consumer safety, and uphold your brand reputation—all without slowing down production.

How is X-ray Inspection Used in Bakery Manufacturing?

X-ray inspection provides an additional layer of security in baked goods processing by detecting non-metallic and metallic contaminants such as glass, dense plastic, and wire fragments. X-ray inspection systems effectively identify a wide range of foreign materials regardless of their composition, including aluminized packaging or high-salt content products.

In bakery manufacturing, X-ray inspection is particularly useful for:

- Detecting embedded contaminants: Identifying foreign materials inside products such as cakes, breads, and pastries where visual inspection is not effective.

- Pre-packaging inspection: Ensuring baked goods are contaminant-free before they are sealed and shipped.

- Quality control: Checking for missing, misaligned, or broken components in products like filled pastries or multi-layered baked goods.

- Weight and shape verification: Ensuring consistency in portion sizes and confirming no voids or air pockets inside baked goods.

By integrating X-ray inspection into bakery manufacturing, food industry producers can enhance consumer safety, meet regulatory requirements, and protect their brand reputation while maintaining high production efficiency.

Final Packaged Product Inspection

Bakery facilities use X-ray inspection as a final step to scan wrapped or boxed products for contaminants. This is important to ensure all products that leave the facility are containment-free to support consumer confidence and brand reputation.

Additionally, X-ray inspection can confirm product quality and consistency by verifying the contents of primary and secondary packaging. Manufacturers can “teach” X-ray systems to recognize variations in package contents, indicating inaccurate item counts, damaged products, or poor seals.

CASSEL Inspection’s XD28 and XD38 X-ray inspection systems are built to meet the specific needs of bakery manufacturers, ensuring that every package leaving your facility meets the highest safety and quality standards.

How Are Checkweighers Used in the Bakery Industry?

Accurate portioning and weight control are crucial in bakery production to prevent underfilled or overweight packages. The Teltek C80 Checkweigher ensures compliance with weight regulations and helps bakery operations optimize their production process.

- Individual Item Weighing: Ideal for individually wrapped cookies, snack cakes, or multipacks, ensuring each item meets the expected weight range.

- Batch and Case Weighing: From small clamshell containers to bulk bakery boxes, checkweighers verify total package weight to avoid costly overfill or underfill issues.

- Product Giveaway Prevention: Overfilled packages result in lost revenue, while underfilled packages risk compliance violations and customer dissatisfaction.

With fast, accurate weight measurements and automatic rejection of non-compliant products, our checkweighers help bakeries maintain consistency and efficiency across their production lines.

.png)

Why Choose CASSEL Inspection for Bakery Product Inspection?

For over 30 years, CASSEL Inspection has provided industry-leading inspection solutions for food manufacturers worldwide. Our systems are tailored to meet the specific challenges of bakery production, ensuring:

- Reliable contaminant detection for metal and non-metal foreign materials.

- Seamless integration with existing production lines.

- Compliance with industry safety standards, including HACCP and FSMA.

- Customizable solutions designed for high-speed bakery operations.

If you are looking for an inspection system to enhance your bakery’s safety and quality assurance, contact us today to speak with an expert and find the perfect solution for your facility.